How to perfectly measure box dimensions in 2 easy steps

Custom packaging is exclusively tailored to perfectly fit the product it’s designed for. However, to create winning packaging, you have to know the exact box measurements. Ensuring the precise length width height of a box guarantees that it’s neither too big nor too small for the intended product. Eventually, minimal space for product movement promises minimal product damage during transit and handling.

Using the right-sized box reduces the need for extra packaging materials like inserts, padding, etc. which cuts down the additional cost. Moreover, box dimensions let you determine how much material is required alongside giving a hint of the cost of production, shipping, and warehousing. Hence, it allows you to take calculative moves towards creating the perfect custom box for your product.

While measuring the dimensions of a box is not rocket science, the accuracy requires a little more attention to detail. As a help, we have provided a quick and simple guide on how to measure a box with accurate length, width, and height. Moreover, in this guide, you will get to explore some key tips and tricks to take the perfect measurements. Now go grab your measuring tools and let’s get started.

Calculate the Three Dimensions

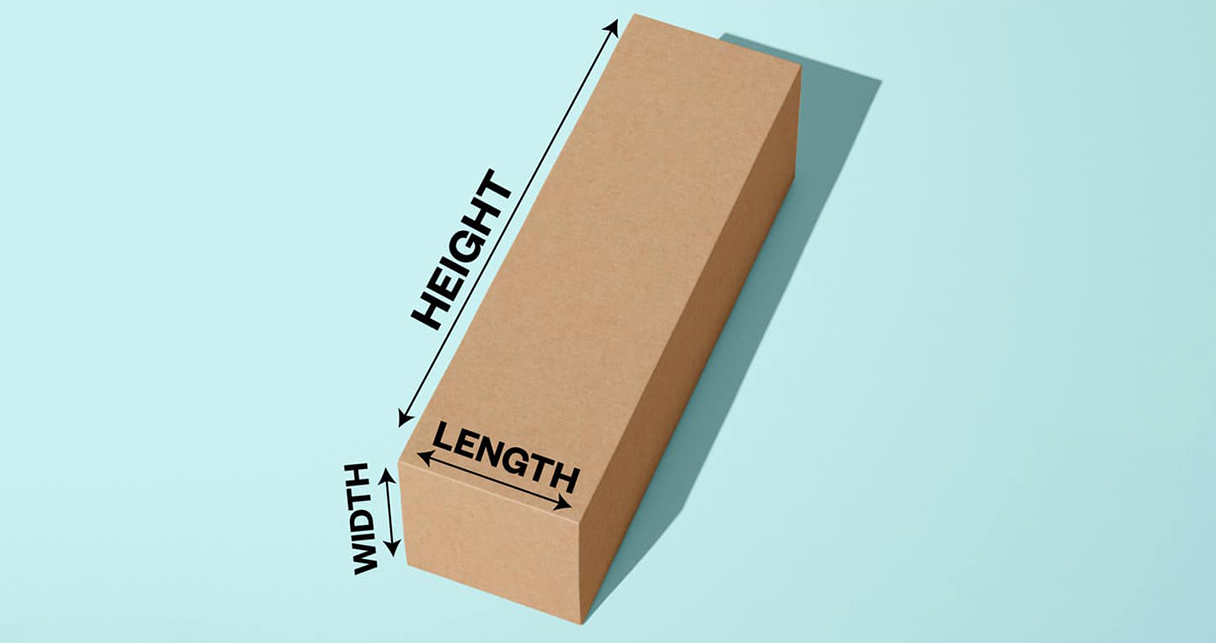

The first step involves calculating the three package dimensions i.e. length, width, and height of the box. However, to ensure accurate measurements, you need to distinguish between each of these three dimensions i.e. length vs width vs depth.

· Length: It is the longest side when viewing the box from the top

· Width: It is the shorter side when viewing the box from the top

· Depth (Height): It is the distance between the top and bottom of the box.

The industry standard box dimensions order is Length x Width x Height or Length x Width x Depth. However, the dimensions are always taken from inside the box, rather than outside. It is to determine whether the product will fit in or not.

Now let's get a bit practical

Grab a ruler or tape and measure the width depth height of the box in both inches and millimeters. For standard box sizes, you can take measurements in inches, rounding each measurement to the nearest whole inch. However, for a bespoke box, it is essential to measure in mm so that you can get the most precise measurements and create the exact box sizes as required.

Pro Tip:

Measure multiple times and take the average to reduce any potential error.

The Key to a perfect measurement:

Now that you know how to measure lxwxh of a box. Considering the shape of the box is now the key to taking the perfect measurement each time as it impacts the dimensions of a box. Getting confused? Let’s clarify with a few examples.

Tall or Upward Facing Box:

In this kind of box, the depth is the most prominent dimension of the box as it is much longer than the length and width.

Long Length Box:

In the long-length box, just like a traditional shoe box, the height and width are much smaller than the length of the box.

Hence, package dimensions are not just limited to rectangular boxes but irregular shapes as well such as hexagonal or triangular boxes. In such cases, the width depth height of the box refer to different edges or sides of the box, depending on the unique custom shapes.

Calculate the Volume of a Box

After calculating the length width height of the box, the next step is to find out the volume i.e. the internal capacity of the box. This will determine how much room is inside the box and how well your product is going to fit in it. To make sure that your product snugly fits in the package and remains secure throughout the shipping and handling, it is crucial to find the accurate volume of the box. To do so, you simply have to multiply the calculated dimensions using the below-mentioned formula.

Length x Width x Depth = Volume

The obtained measurement is the internal capacity of your box and it is going to be in cubic centimeters. By knowing the accurate volume of the box, you can optimize material usage, reduce costs, and manage the structural engineering of your custom packaging effectively.

Why internal dimensions?

As we discussed earlier, the industry standard for box measurements refers to internal measurements rather than external ones. Although it might seem pretty straightforward to grab a tape or ruler and measure a box from the outside, however, it's the internal dimensions of the box that matter the most.

The interior dimensions determine whether your product is going to fit the one window packaging or going to have a roller coaster ride inside the sliding box during shipping. So an accurately measured box interior helps you create the perfect package that snugly fits the product inside. Leaving no room for product movement ensures your product safety during both shipping and handling, promising your product quality and brand integrity. It also reduces the need for extra cushioning or padding, which cuts down the additional costs.

The external calculation can be a miscalculation

Measuring the external dimensions of the packaging is not the best practice as it doesn’t count the thickness of the box. It is particularly important in the case of corrugated boxes. A corrugated box is made of a thick sheet that comprises a fluted texture sandwiched between 2 layers of paperboard. This triple-layered sheet adds up a few millimeters to the measurement that is taken from outside the box lining.

So the external dimensions of the box don’t give precise measurements but can be a miscalculation instead. Hence, it could result in packaging that doesn’t meet your desired box size and fail your idea of a perfect custom box.

Now that you are familiar with box dimensions and know how to precisely calculate the length, width, height, and volume of a box, measuring the dimensions of any kind of box would seem like a piece of cake, right? So note these easy steps as your fool-proof box measuring guide and create custom boxes that never fail to impress.